Description

Resilient Seat Gate Valves – Introducing Our Robust and Versatile Valves

Crafted for Reliability and Performance

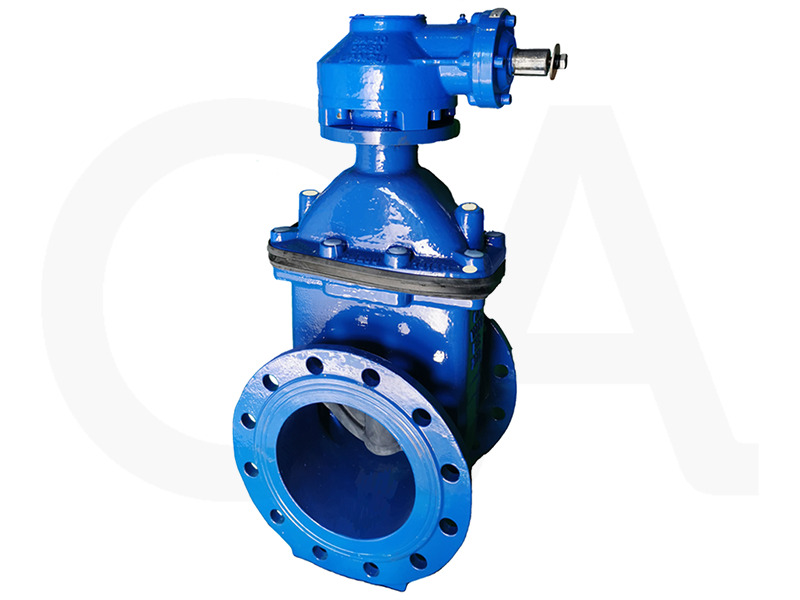

In the realm of water management, reliability and performance are paramount. Here at GA Valves, we take pride in offering resilient seat gate valves meticulously crafted to meet the demands of clean potable water systems.

Built for Strength and Endurance

To begin with, our valves feature a robust ductile iron construction, ensuring they can withstand the rigours of daily operation with ease. Additionally, the blue fusion bonded epoxy coating, applied in accordance with BS EN 14901 standards, provides exceptional corrosion resistance, guaranteeing longevity and durability.

Facilitating Smooth Flow

Moreover, at the heart of our resilient seat gate valves lies a commitment to optimal flow. With a full clear bore design and a stainless steel stem, our valves ensure smooth and efficient water flow, minimising disruptions and maximising efficiency.

Customisable Solutions to Suit Your Needs

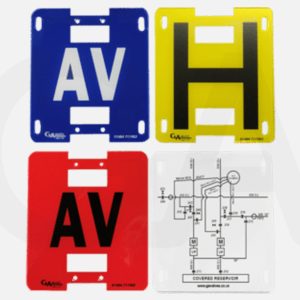

Furthermore, we understand that every application is unique. Therefore, we offer a range of features and options to cater to your specific requirements. From handwheel or cap top operation to clockwise or anti-clockwise functionality, we have you covered. Plus, with accessories like chain wheels, extension spindles, and locking devices, customisation is effortless.

Rigorously Tested for Quality Assurance

It’s important to note that our valves undergo rigorous testing to ensure compliance with the highest standards, including EN12266 inspection and testing protocols. With a shell test rating of 24 bar and a seat test rating of 18 bar, along with a suitable temperature range of 0°C to 80°C, you can trust our valves to perform reliably in any environment.

Committed to Excellence

In conclusion, at GA Valves, we’re committed to delivering excellence in every aspect of our products and services. For further information or assistance, please don’t hesitate to contact us. Your satisfaction is our top priority, and we’re here to help every step of the way. Trust GA Valves for all your resilient seat gate valve needs – because when it comes to water management, excellence is non-negotiable.