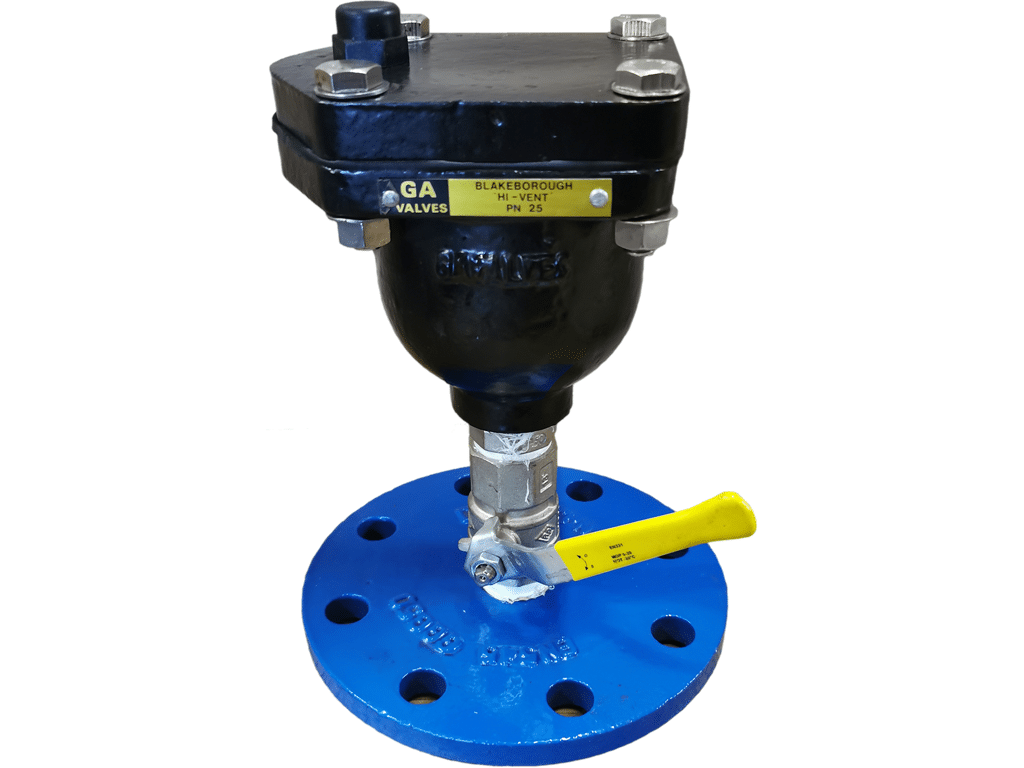

Description

Usage for potable & filtered water

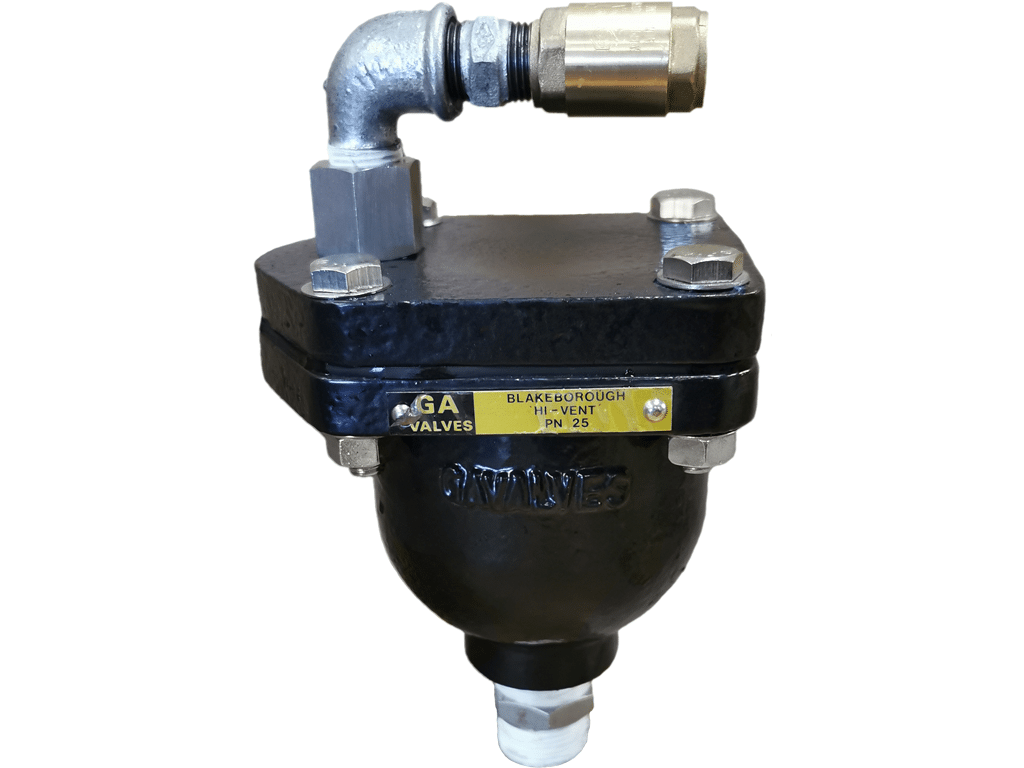

During normal working of the main the valve releases the air which accumulates under pressure.

With the main in operation, the float is normally against its seat.

As air enters the body the water level is depressed until a level is reached when the float drops from its seat, which allows air to escape.

The consequent rise in water level returns the float to its seat.

Efficient low pressure sealing at 0.3bar.

Lightweight design.

WRAS approved.

2.3mm (4.1mm2) orifice.