Air Release Valve Longevity by Material: Stainless Steel, Ductile Iron, and More

Air release valves are critical for removing trapped air from pressurised pipelines. While the function of the valve is consistent, the material you choose can dramatically affect longevity, maintenance, and total cost of ownership. Common materials include stainless steel, ductile iron, bronze, brass, and engineered plastics. Each offers different strengths, weaknesses, and lifecycle costs depending on your application. This guide compares the most widely used materials to help you make a more informed decision.

Why Material Choice Matters

- Corrosion resistance: exposure to water chemistry, chlorination, or saline environments

- Mechanical strength: ability to withstand high pressures, stress, and temperature cycles

- Maintenance demand: coatings, re-lining, and inspection requirements

- Cost vs lifecycle: balancing upfront purchase price against replacement cycles

Stainless Steel Air Release Valves

- Longevity: Excellent — can last decades, especially in aggressive or coastal environments.

- Strengths: Corrosion-proof, wide operating range, low maintenance.

- Ideal For: Potable water, desalination plants, petrochemical, industrial, coastal.

- Considerations: Higher initial cost, but lowest long-term lifecycle cost.

Ductile Iron Air Release Valves

- Longevity: Very good — strong and durable when coatings remain intact.

- Strengths: High tensile strength, cost-effective, proven in municipal systems.

- Ideal For: Clean water distribution, irrigation, general infrastructure.

- Considerations: Coating damage shortens life; more frequent inspection needed.

Bronze Air Release Valves

- Longevity: Good — resistant to corrosion but softer metal than stainless steel.

- Strengths: Excellent for smaller valves and systems with moderate conditions.

- Ideal For: HVAC, small-scale water systems, light industrial use.

- Considerations: Can wear more quickly under high pressure or abrasive conditions.

Brass Air Release Valves

- Longevity: Fair — adequate for lower-pressure or smaller applications.

- Strengths: Easy to machine, cost-effective, compact designs.

- Ideal For: Building services, plumbing, small irrigation networks.

- Considerations: Not suitable for aggressive water chemistry or high-pressure pipelines.

Plastic (PVC, HDPE, Composite) Air Release Valves

- Longevity: Varies — excellent corrosion resistance, but mechanical limits.

- Strengths: Lightweight, corrosion-proof, affordable.

- Ideal For: Agricultural irrigation, low- to medium-pressure pipelines, chemical-resistant systems.

- Considerations: Not as strong under high pressure; UV exposure can degrade some plastics.

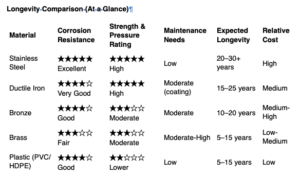

Longevity Comparison (At a Glance)

Summary

When comparing air release valve materials, longevity depends on environment and application:

Stainless Steel: Best for harsh, aggressive, or critical systems; longest service life.

Ductile Iron: Reliable and cost-effective for standard clean water; coating integrity is key.

Bronze/Brass: Suitable for smaller-scale or moderate systems; less durable under stress.

Plastics: Great corrosion resistance at lower pressures; best for irrigation or light-duty use.

Bottom line: If longevity is your priority, stainless steel typically outperforms other materials. If budget drives your decision and water quality is controlled, ductile iron delivers excellent value.

Contact us now to see how we can help you!

Contact us by email at sales@gavalves.co.uk or call us on 01484 711983

Related Posts

Below you can view our related posts.

Guide

Small Air Release Valve for High Pressure Pump Station

High pressure pump stations are critical components in water distribution, industrial processing, and irrigation networks. But with higher

Read More

Resource

Small Air Release Valve for High Pressure Pump Station

High pressure pump stations are critical components in water distribution, industrial processing, and irrigation networks. But with higher

Read More

Guide

Sizing Chart for Small Orifice Air Valve

Small orifice air valves play a critical role in removing dissolved air from pressurised pipelines during operation. To

Read More